There are considerable and complex top-down pressures on farmers to adopt digital technologies. It’s not surprising that many farmers sit on the fence when it comes to adopting technologies. However the digital technology journey should really start with a few simple questions before we take the step to go to the shop, field day or tech expo.

Forget about the tech for a moment and consider the following questions.

- What am I trying to achieve in my business?

- Can I achieve that in a better way?

A few months back I met Gav (not his real name) from the table lands of northern NSW. He was recommended to me by a mutual friend as an innovative livestock farmer. I was inspired by his pragmatism, honesty, and simple approach to technology.

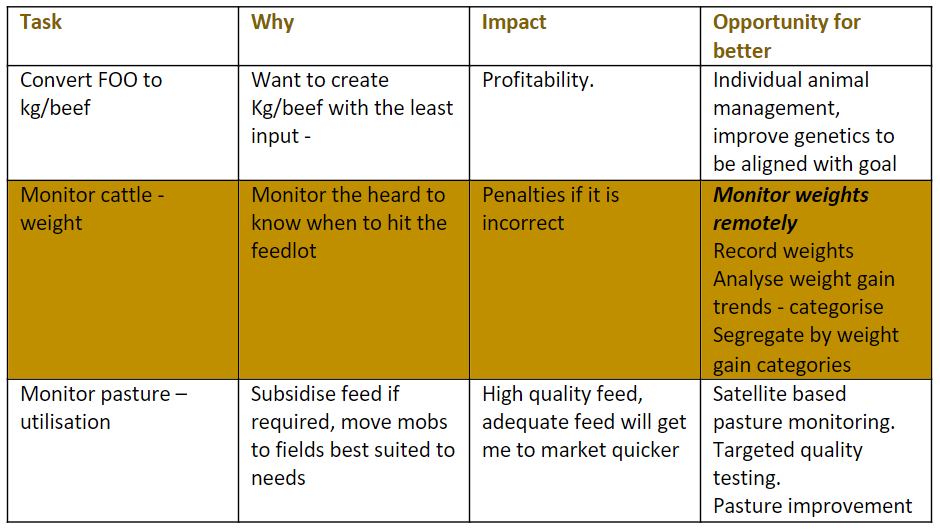

Gav is in the business of preparing cattle for destination feedlot, alternatively known as backgrounding. Over the years Gav had trialled all sorts of technology, constantly seeking the holy grail and was consistently disappointed as his expectations were not appropriate. Upon reflection and review, Gav realised he didn’t have a question in mind that was proportionate to his expectation. He thought about his business model and reminded himself of his very specific goal, to turn over the cattle as quickly as possible. He found it easier to concentrate his efforts on a few tasks only.

Gav started simply with monitoring cattle weights remotely. After investing in a Tru-Test scan system for the cattle yards a few years back, his greatest limitation was labour and bringing cattle in and out regularly. This was a strain on his wife who now primarily looks after 2 children under 3 years old. “I copped a few penalties for several mobs where more than 15% of the cattle were outside of the 10% threshold for correct weight. Lib was pregnant with baby #2 and I just couldn’t ask her to help me reliably. We were coming out of the drought but had a little way to go before cash flow improved, so I needed to find an innovative solution”. Gavin identified that he needed to replace the labour component of moving cattle regularly, and realised that he could store and handle the individual weights more efficiently to eliminate the need for manual aggregation.

He investigated a few products and settled on Optiweigh©, a portable autonomous in-paddock weighing system that uses satellite data connection to send individual weights of each animal to a cloud-based computer.

Gav concedes that he could be doing more with the data, including tracking the non-performers and either segregating, removing, or individually managing them. However he is still working out the value proposition for each scenario before he invests further.

In the meantime, the investment isn’t necessarily making him significantly more money. However it has reduced his reliance on additional labour. Gav has minimised the stress on the cattle and surprisingly, the mob is statistically less diverse in weight gains. With no buyer’s regret the value has come from efficiency, which is always harder to measure.

Next steps include an alternative in-field ‘walk over’ weigh instrument that will automatically draft cattle based on performance in relation to the average. However this would require a few fencing changes and some way to determine the best paddock to put those drafted cattle in. Alternatively upgrading his current Tru-Test system and investing in an automatic drafting gate for the yards could be an option. The decision will be determined by some analysis of when it makes best financial sense to intervene. Stay tuned.

Tips from Gav:

- Keep it simple at the start.

- Try to fix only one ‘problem’ at a time.

- Choose technology that makes life simpler not harder.

- Analytical power is great but be honest about what you willing and able to respond to.

- There are still lessons to be learned for many products, so keep your eyes wide open and be willing to work with the vendors. Remember to provide feedback.

Author | Brooke Sauer, IntellectAg